【Intelligent Technology】

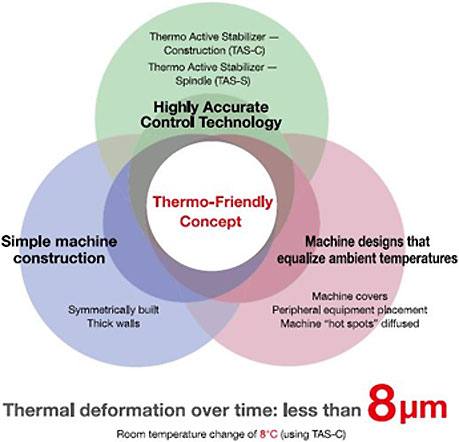

Thermo-Friendly Concept

“Working with temperature changes”

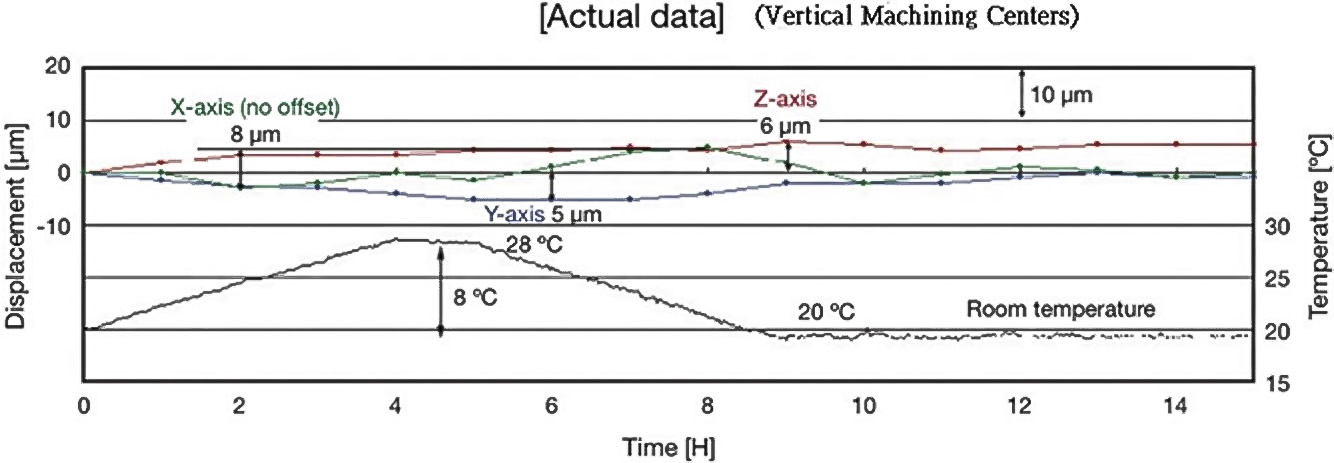

- Okuma’s Thermo-Friendly Concept is a structurally designed, thermal deformation control technology that provides astonishing cutting accuracy. It frees the operator from troublesome machine warm-ups and offsets.

- During long production runs with changing shop temperatures, the required part dimensions remain stable.

(Vertical Machining Centers)

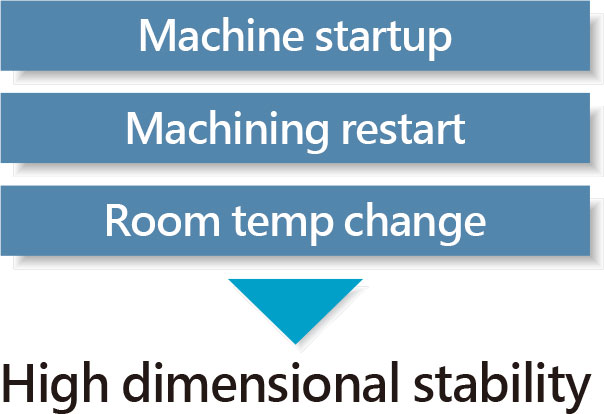

Eliminate waste with the Thermo-Friendly Concept

In addition to maintaining high dimensional accuracy when room temperature changes, Okuma’s Thermo-Friendly Concept provides high dimensional accuracy during machine startup and machining restart. To stabilize thermal deformation, warming-up time is shortened and the burden of dimensional correction during machining restart is reduced.

“Proactively” keeps the machine [construction] in optimum, stable condition during shop environment temperature change- resulting in superb (stable) machining accuracies.

Accurate compensation during spindle start/stops, and speed changes.

Machining Navi

Cutting condition search function for turning

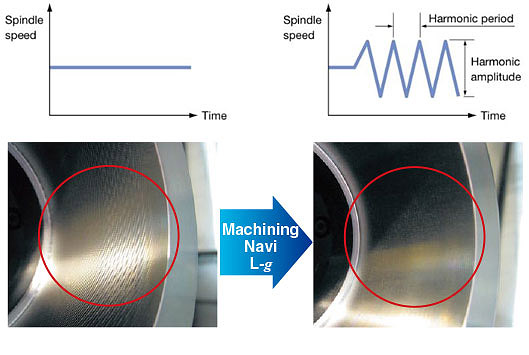

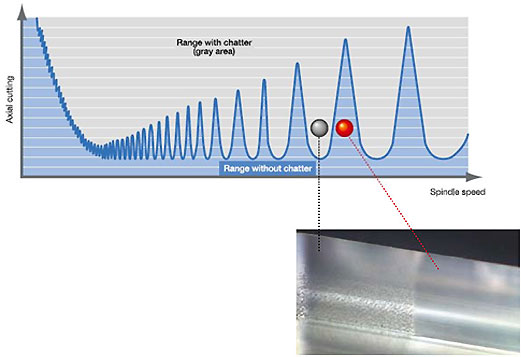

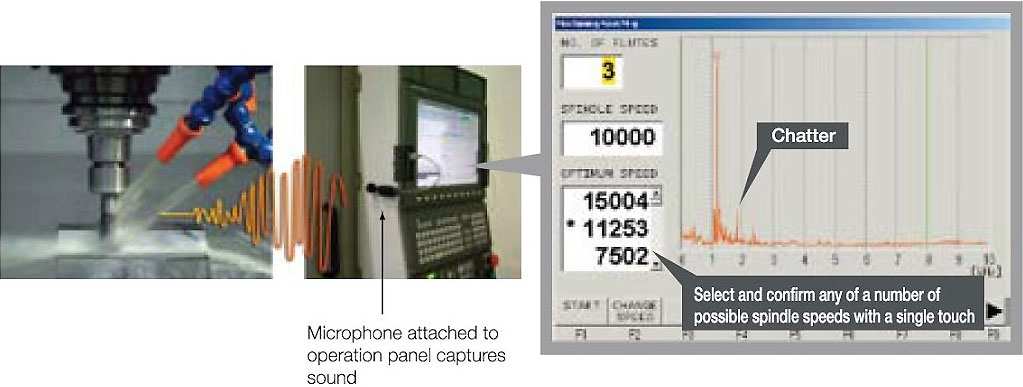

Machining Navi L-g (guided, harmonic spindle speed control )

Varying the spindle speed in accordance with the best amplitude and period makes it possible to suppress chatter during turning operations. Tool life can be extended and machining time reduced with use of the optimum cutting conditions, producing significant effects in drilling/boring bar, threading, and grooving applications.

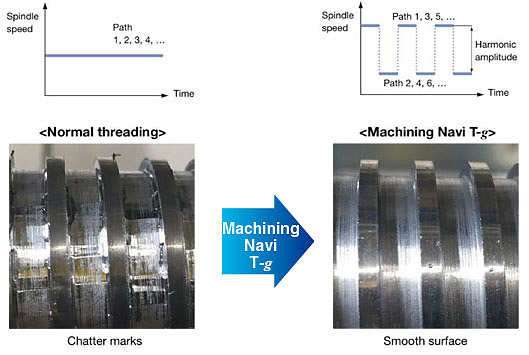

Cutting condition search in threading

Machining Navi T-g

When chatter occurs in threading, general methods to resolve the problem have been to either lower cutting conditions at the expense of productivity, or to use special chatter-resistant tools at some cost. Machining Navi T-g (threading) provides optimum control, increasing or decreasing spindle speed on each pass to inhibit the periodic vibrations that are a cause of chatter.

Machining Navi M-g (Optional)